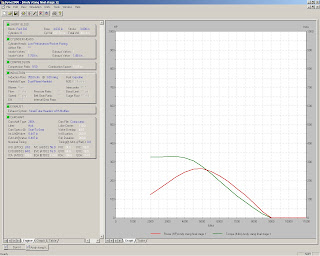

but most of my engine design is done on a computer. This is kind of a newer way to do this. I figure its better then scratching my head and throwing parts in my cart on summit racing. Ive read reviews on a few different programs, they all seem to claim to be within 10% accurate. I dont have acess to a dyno to prove or disprove but It honestly seems likely. Ive never had anything come back at an odd number.

soo anyways back on point, I thought i would at least(try) to put up a Design I've been putting together for a while. Very basic, But very effective for what its for.

The program is a little outdated( desktop dyno 2000), I have a newer one That is less user friendly as this, But I still enjoy using this one. The other one that I also use from time to time(when im shopping for camshafts) is comp cams Camquest. This is set up similar to desktop dyno but instead of you typing in the cam specs you select a cam from comp cams products. still effective, IF your planning on using a comp cam.